Fusion 360: the right 3D modeler for 3D printing?

Autodesk offers multiple 3D modeling software solutions, the most well-known being AutoCAD. It is the design software of choice for architects, engineers and construction professionals. Even though it is possible to create 3D models with solids, surfaces and mesh objects on AutoCAD, it is much more advanced in terms of its 2D capabilities. Therefore, Autodesk has developed other software dedicated to 3D modeling applications such as Fusion 360 or Tinkercad. As its name suggests, Fusion 360 aims to be a full solution, offering CAD but also CAM (computer aided manufacturing) and CAE (computer aided engineering) tools. For additive manufacturing applications, it is a software that is easier to use than AutoCAD as it aims to facilitate product development. So what are its features?

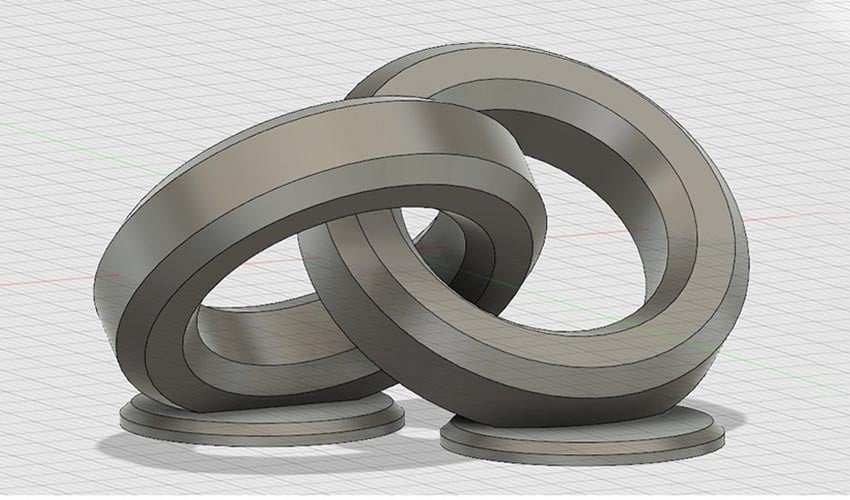

As mentioned, Fusion 360 is cloud based and integrates CAD, CAM and CAE tools to unify design, engineering and manufacturing into a single platform. Essentially, you will not have to leave your design environment when modeling on Fusion 360. Fusion 360 enables mechanical and technical 3D models to be created. One recurrent comment from users is that the software is limited in terms of organic modeling because it does not offer many sculpting tools. Therefore, more artistic models are not really possible on Fusion 360. For this type of modeling, solutions such as Blender or Rhino will allow you to achieve much more.

Fusion 360’s interface

Fusion 360: what are the features?

As you know, there is a specific format needed to be able to send a 3D model to a 3D printer, and Fusion 360 is perfectly suited for this. You can save your 3D model in a variety of formats including .STL and .OBJ. In terms of 3D modeling, Fusion 360 offers sketching, parametric modeling, direct modeling, freeform modeling, surface modeling, sheet metal, mesh modeling, assemblies and PCB design integrations. Therefore, it covers all the needs industrial designers may have when developing a product, combining aesthetics and function.

One of the benefits of the 3D modeling software is that it is cloud-based, which means that the development process is unified between different designers and engineers. Fusion 360 is also a platform for collaboration between different parties. It is possible to connect different teams and external stakeholders on the same project, communicate in real time and centralise project activity.

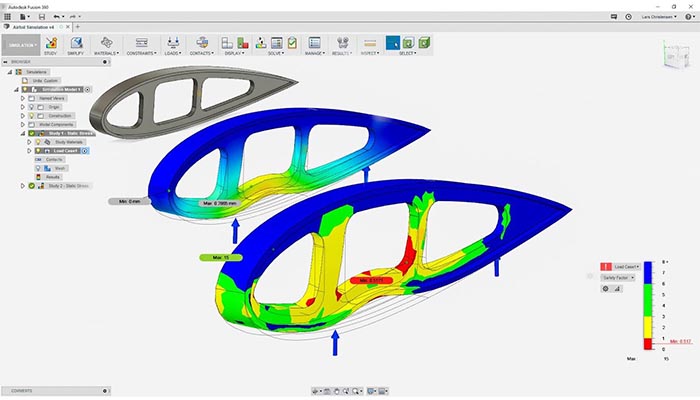

Given that 3D printing enables a great amount of design freedom, it’s also important to have tools that can leverage this feature in the software. Fusion 360 offers generative design tools to explore multiple manufacturing outcomes that meet the design specifications you will have defined. For example, it will be able to propose designs to reduce weight, improve performance and consolidate parts. On top of this, it would not be a full solution if it did not include simulation tools. Simulation tells designers and engineers if their models will survive real-life applications, and can therefore reduce the price of prototyping. This is a key aspect of developing any prototype, which is often what companies use 3D printing for.

In terms of ease of use, many users point out that the software is relatively new in the market. Therefore some tools are extremely advanced, others such as organic modeling not so much. However, if you aim to use it to design mechanical parts, it has the right degree of complexity and collaboration tools to facilitate this type of modeling. Additionally, many resources are available online to teach you how to use the software and the learning curve is not as steep as other CAD solutions. Autodesk provides a free trial for up to 30 days to test out Fusion 360. After this, the licence costs $495 per year for any user. You can find more information on Autodesk’s website HERE.

Do you have more questions about Fusion 360? Tell us in a comment below!

Post a Comment